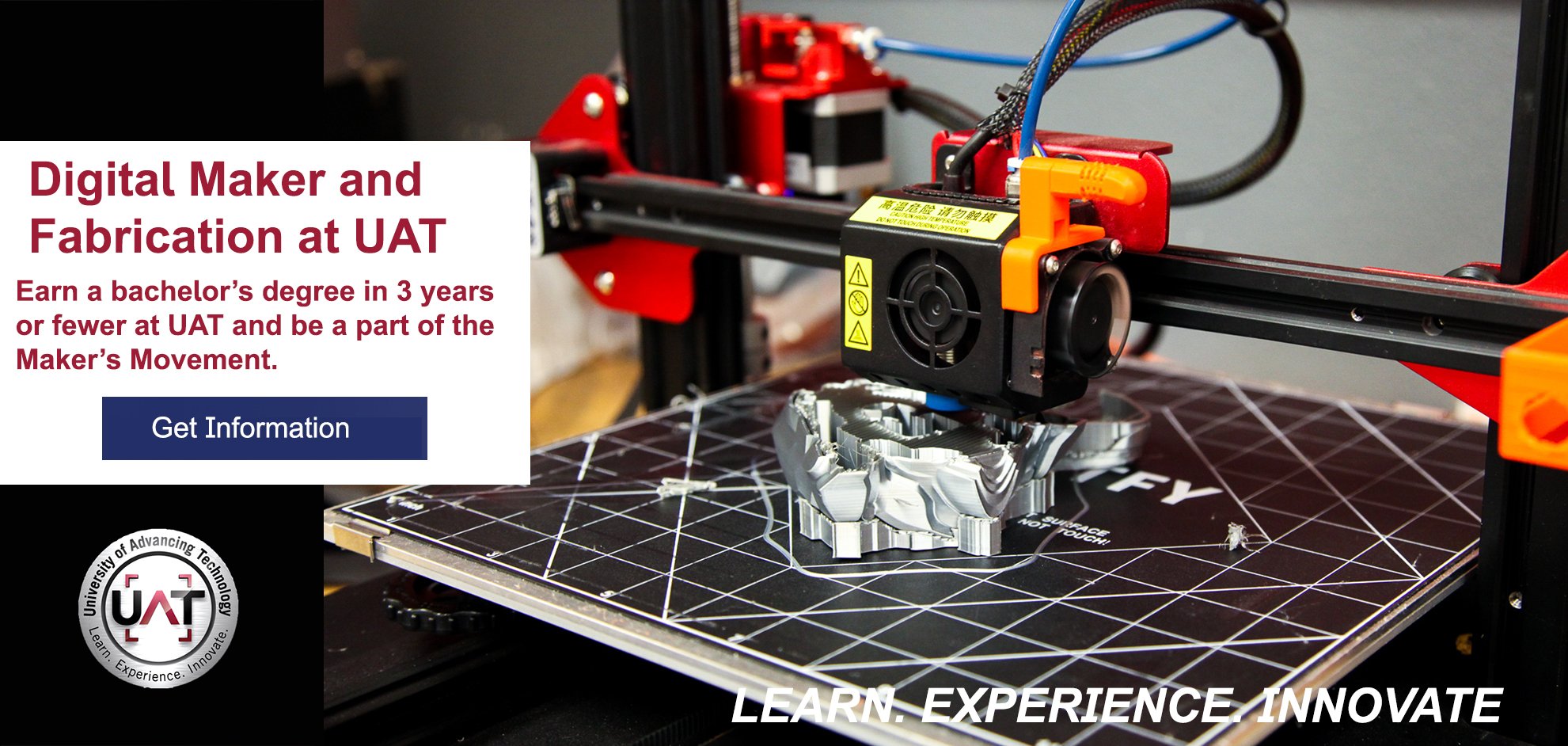

Digital Maker and Fabrication Degree

Technology forecasters claim that the future is digital. This prediction applies to tech-centric careers and in traditional industries where work is performed manually. A new industrial revolution is unfolding and this time–it’s all about digital manufacturing.

Digital modeling and fabrication involves the use of computer design and 3D models to change, enhance, or produce new manufacturing workflows. In 2020, the value of this industry exceeded $260 billion dollars.

While the future looks bright, many students wonder whether they should specialize or choose a degree in digital fabrication.

In this post, we’ll share what you can expect to gain and accomplish with a Digital Maker and Fabrication degree.

What is Digital Maker and Fabrication?

Digital fabrication is a modern method for designing and producing goods that combines computer-aided design (CAD) with additive manufacturing (3D printing). This combination results in intelligently designed products that enhance the user experience.

Digital maker and fabrication is more than just 3D printing, as many people wrongly assume.

In fact, fabrication methods involve both additive and subtractive technologies that assist with bringing digital design ideas to physical conception:

- Additive technologies are those that produce three dimensional objects layer-by-layer. Computer-aided-designed (CAD) is the means of creation.

- Subtractive technologies begin with a solid block of material and create the finished product by drilling, chipping, or removing excess material.

Digital makers learn how to leverage both technologies to produce the intended final product or design.

What is the Digital Maker Movement?

The “Digital Maker Movement” is a way to describe the rise of digital tools, fabrication methods and creative computer systems as they relate to production and manufacturing.

These innovations revolutionize the way that humans create new inventions and bring physical products to market. Additionally, the “Internet of Things'' culture means that there is extra attention on how human beings interact with and benefit from computer-generated systems and products.

The maker movement enhances this progress through creativity and innovation. At University of Advancing Technology (UAT), we recognize and embrace the Digital Maker Movement and equip students with both the educational and practical tools required to pioneer new solutions.

Skills Associated with the Digital Maker Movement

Digital fabrication requires a strong skill set based on technological aptitude. In order to excel in a future digital fabrication career, students should be well versed in the following foundational skills.

- Computer programming

- Computer-assisted-design (CAD)

- Parametric modeling

- Topology optimization

- Kinematics

- Electronics

- Metallurgy

- Additive manufacturing

- 3D printing

In addition to these hard or technical skills, students pursuing a digital maker and fabrication education should be creative, open-minded and innovative. Since this field requires invention and problem-solving, many learners are very tactile and hands-on.

Although not required, digital makers may also need to be persuasive, particularly as they introduce or advocate for new technologies and processes in traditional settings. For example, digital makers may need to use persuasive skills to revamp outdated manufacturing techniques and introduce computer-assisted design into the workplace.

What Can You Do with a Digital Maker and Fabrication Degree?

A Digital Maker and Fabrication degree provides plenty of occupational options to students. Given the relative newness of digital fabrication in the modern business marketplace, many students have the potential to forge their own career paths in exciting industries.

A Digital Maker and Fabrication degree serves as a launching point for careers based on skills such as:

- Prototyping– With the use of CAD/CAM software, more companies are relying on digital prototyping to develop new products and services.

- Additive manufacturing– Skills like 3D printing enable manufacturers to save time, improve workflows and produce new physical material to meet rising consumer demands.

- Robotics– Robotic solutions are becoming increasingly prominent, particularly in fields like healthcare and automotive manufacturing.

- Patent development– Bringing new inventions to market involves a thoroughly tested and vetted process; digital makers know how to effectively establish patents for fabricated products and goods.

- Technology selection– Being a digital maker involves recognizing the most appropriate design strategy and tools for a particular job. Each design element requires the right hardware, software and computer programming language.

If these specialty areas pique your interest, explore the possibilities of what a Digital Maker and Fabrication degree and technical training program can mean for your future career.

What Jobs Can You Get with a Digital Maker and Fabrication Degree?

A Digital Maker and Fabrication degree allows students to excel in a variety of fields and disciplines. While many of these jobs are related to manufacturing, others are independent and entrepreneurial.

When applying for Digital Maker and Fabrication (DMF) jobs, you can expect to encounter titles such as:

- Manufacturing Technician

- Technical Manufacturing Manager

- Digital Manufacturing Engineer

- MFG Engineer

- Manufacturing Systems Analyst

- CAD Engineer

- Fabricator

- Digital Manufacturing Strategist

- IoT Analyst

What is the Expected Salary for a Digital Maker and Fabrication Career?

While the average base salary for Computer and Information Systems careers in the United States averages around $88,950 per year, many open positions include salary ranges from $100,000-$130,000 per year.

Expected salary ranges are based on years of experience, areas of expertise and the global needs of the hiring company.

Effects of Digital Fabrication Across Industries

Despite its relative newness, digital fabrication is changing the way that human beings design, create and invent new physical goods and solutions. Digital modeling software is useful in almost any industry and it provides numerous benefits to modern consumers who want more access to affordable and reliable products.

In addition to improving business manufacturing processes, digital fabrication is also crucial for crisis response and humanitarian aid in a world with evolving threats and disasters.

Having the ability to access, produce and distribute life-saving goods and materials is one extremely important way that digital fabrication has a huge part to play in the future of society.

Digital Maker and Fabrication Degree Programs

The Digital Maker and Fabrication Degree is relatively new when it comes to technological education, but the field is expanding every year. This growth provides students with several options when choosing the degree or certificate that best suits their needs and career goals.

Flexible Online Degree

Given the modern nature of remote learning, many fabrication programs can be easily completed in an online format. This provides flexibility to different types of learners, particularly adult learners who may be looking for a career change.

At UAT, faculty in the Digital Maker degree program receive extensive training to help students succeed in an online learning environment. During each class session, course instructors actively participate in online lectures and discussion groups and respond to student questions in a timely manner. These steps create a more engaging, in-depth learning experience.

Associate's Degree

An Associate’s Degree in Digital Fabrication provides a basic foundation to the skills and computer programs needed to excel. These degrees may provide apprenticeship and internship opportunities that can be helpful for a student’s next educational step.

Bachelor's Degree

A Bachelor’s Degree, such as the Digital Maker and Design Program at UAT, provides students with comprehensive coursework to develop technical skills. A Bachelor’s degree is typically a more full-time program that requires a completed work portfolio, internship and capstone project.

At UAT, all students approach graduation ready and able to apply for an official U.S. Patent on their product or invention of choice.

Graduate Certificate

Graduate certificates are typically shorter (12 credit hours or less) programs that offer additional training or professional development to individuals with foundational knowledge of design and fabrication.

These types of programs are often more hands-on and may require in-person instructional time to complete coursework or a faculty mentorship. There is usually a practicum or final project that summarizes a student’s work and achievement in fabrication skills.

Is It Worth Getting a Degree in Digital Fabrication?

If you’re a creative thinker with a mind for computer-assisted design, digital fabrication is an excellent degree choice. Fortunately, the potential for new opportunities is significant.

In the next five years, digital fabrication and manufacturing is expected to reach a value of over $700 billion globally across multiple industries. Not only does this mean that more jobs will become available, but it also means that getting a foot in the door now is a smart move.

More businesses and cultural leaders are recognizing and leveraging the benefits of digital fabrication.

Some of these advantages include:

- Time savings

- Reduced processing costs

- Increased automation

- Digital growth based on analysis and data

An education in digital fabrication can establish you as a trailblazer in a career field with untapped potential and limitless innovation.

Earn a Digital Maker and Fabrication Degree at UAT

UAT offers a Bachelor's Degree in Digital Maker and Fabrication. Our degree program is the nation’s first fully-accredited Bachelor of Science Degree in Digital Maker and Fabrication and it falls in line with our leadership in advanced computer technology education.

If you think a digital maker or fabrication degree is the best fit for your goals and skills, request more information about our degree programs. At University of Advancing Technology, we look forward to providing hands-on, practical STEM experience from the very first day in class, all the way through graduation.

Comment